Tips for Buying the Best Metric Thread Gauges

Are you looking for a metric thread gauge that will give a long lasting solution? Or you have been buying metric thread gauge that are offering you the best services that you need. There are times you seem stuck not knowing where to get started in an attempt to buy the metric thread gauge that you need. The are many firms that are selling the thread gauges that might offer you the services that you want and make it a further challenge of buying the gauges all the times, however this particular challenge can come an end if you know where to get the best metric thread gauge that you need. The first thing you must take into consideration is the cost of the metric thread gauge you want to buy.

There are many stores that are selling the gauges at a very expensive prove making very difficult for people to buy, therefore it is very important to have a proper look at the prevailing market price for you to have the best deal that is pocket friendly and at the same time ensure that you save on your cash form buying the metric thread gauge. Another important thing is to check whether a dealer offers a variety of the gauges that you need. It sometimes very hectic to look for the metric gauges at different place making an exercise in futility and a waste of time for moving from one dealer to another, therefore to avoid this kind of a situation it is good to have a dealer that offers all gauges that you may need under one roof. Apart from the variety, one must also check into the experience that a dealer has in selling the metric gauges this comes with an assurance that you will get authentic gauges that will serve better.

Read more at ACME thread gages.

How to Find the Best Online Supplier of ACME Thread Gages

If you use a lot of ACME thread gages in your business, you are probably always looking for a supplier that can sell them to you for a cheaper price than what you are currently paying.

If so, and you have not yet looked for a suitable supplier of ACME thread gages on the Internet, then you are making a mistake.

Not only can a good online supplier of ACME thread gages save you money but, in some cases, you may even find the thread gages they sell you are even better quality than what you have used in the past.

Look for a manufacturer of ACME thread gages -- While finding an online thread gage seller is a good start, buying from a manufacturer is a better bet.

This is because not only are they selling their own products so can afford to cut their prices even more, they should also be able to custom manufacture any ACME thread gages that you may need.

Look for overseas manufacturers -- To get the low prices you want and the high quality you need, it pays to look at overseas thread gage manufacturers first.

Look for those located in Thailand, Vietnam, China, Brazil and Argentina. Manufacturers located in countries like this can offer you the exact thread gages you need, but still manufacture and then ship them to you for an affordable price.

Look for manufacturers with a large international client base -- Companies that already sell to many overseas clients are used to dealing with them and that means they will also be easy to deal with for you.

Look on the website of any ACME thread gage manufacturer you find and see if they list where they normally sell to. This will give you a good idea of where their client base is located and if they have the international experience you need.

ACME Thread Gages Info

Workers may have a use for A C M E thread gauges. These pieces may be used as needed on site work. That makes it easier to complete any ongoing project while working together. Have some foresight and buy the A C M E thread gauges in advance. There is a supplier found online that works to distribute these components. People want to enjoy the shopping experience and appreciate the opportunity. Many different sizes of A C M E thread gauges are already in stock.

These components use Metric measurements to keep them organized. Get to know the Metric sizes and how they influence standard use. That may be best left up to the project lead on location. A foreman can take the lead during the purchase process. They should evaluate the A C M E thread gauges and how they are distributed. Customers have been pleased with the experience that they found in the stores. That makes it easier for project leaders to complete the transaction.

All pieces are sized according to need and standard use. That should be familiar to experienced workers on location. These workers can put in an order for A C M E thread gauges. That supply will be delivered as requested to those involved. Delivery is decided by the order placed online as well. Look for the internal thread to be sized appropriately. That may determine whether the team needs a specific size as ordered.

Add the ACME thread gages to the online shopping pushcart. The online shopping pushcart has made the experience more enjoyable for everyone involved. Trust the manufacturer when it comes to meeting demand from workers. They can put in a request for A C M E thread gauges at a reasonable cost. Prices are determined by the manufacturer, based around cost of production. Shipments will be made by a certain deadline, with just a nominal fee added to totals.

ACME Thread Gages

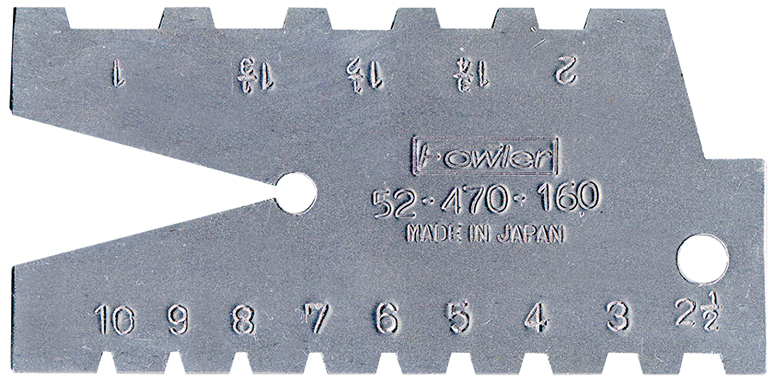

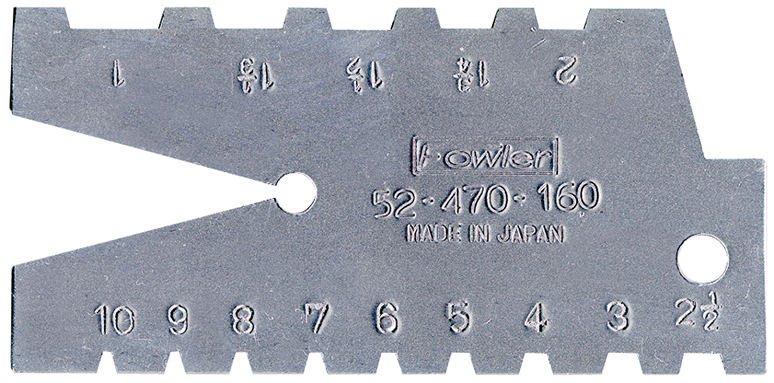

A C M E Thread gages is used to measure screw thread pitch. There are three gauges used- the uppermost gauge, the center, and the lower for Whitworth screws. Thread Pitch Gauge is used to determine pitch, that is on a screw. It allows the user to determine the thread and categorize the shape.

You can use a standard cutter, which is 60 degrees. Once you have made the proper adjustments, you can grind at an angle of 4 degrees. You would then move up to an angle of 14.5 degrees, by holding the HSS lower belt. You will then need to check the gauge to make sure there are not gaps between the thread and the gauge. If there are no gaps, you will need to make corrections.

You will also need to spread some time, grinding for optimum results. You must also remember to no allow the process to overheat. The next step is to put a 0.5 inch to face the end to provide tailstock. You can then start normal threading and choose the length of the A C M E Thread rod and make the proper threading. You will repeat the process, to get positive results.

ACME thread gages also used for translation motion in machine tools. The specifications are ASME B15-1997, thread plugs, rings, check plugs, and TPI from 16 to 2. The popular Unified Thread Gauge is used for the purpose of measuring the lead or pitch of a screw. The Metric Thread Gauge is used to measure the sizes of the wrenches, nut and bolts, the NPT Gauge provide range, the Recoil Thread is used for checking tapping, Iso Metric Thread Gauge resist corrosion and PG Thread Plug Gauges are used for checking thread of pipe fittings.

Where to Find Affordable ACME Thread Gages on the Internet

Where to find affordable ACME thread gages on the Internet

If you need to buy ACME thread gages, and are going to be buying them online for the first time, here are a few tips to help you find them at an affordable price.

Tips that will also ensure you purchase your first online order of ACME thread gages from a reputable shop.

Look for a shop based outside the United States -- While it is nice to be able to buy American, most of the time the more affordable ACME thread gages are found in stores that are based outside the United States.

These stores often offer their products at such a low price that, even with the addition of higher shipping fees due to your order being mailed from overseas, you will find their prices stills stay cheaper. As overseas shipping only adds a couple of extra days onto the time it takes to receive your order, you will not spend much more time waiting either.

Shops that have been in business for a while -- Avoid purchasing from stores that are new, as you will not be able to find out much about their reputations.

Instead, stick with stores that have been in business online for a few years. That way you will be able to read online reviews about them, and check into their reputations easily before ordering.

Custom order ACME thread gages -- Be sure to choose a store that offers custom orders. After all, while you may need standard ACME thread gages at the moment, you do not know when your next order may become more specific.

Good customer service -- Finally, be sure the store you order your thread gauges from has good customer service.

You can find this information by reading what their shop policies are, looking at their rating on the Better Business Bureau website and reading reviews actual customers have written about them.

Acme Thread Gages

Acme Thread Gages

What can I say about thread gages that you don’t already know? Did you know that they are used for measuring the inside of threaded cylindrical surfaces? Pricing is provided upon request to the customer. There are many different sizes to choose from to suit any need.

Do you want quality? Of course you do. With thread gages you will get this. Time and again this brand produces quality products which also enable the project operator to produce a quality product for other customers. Versatility is also one of the key ingredients associated with this product. Anything over 5.0 is priced upon request. Many classes of fit are available which 2c, 3c are, and and4c.Featured with threads is a 29 degree angle of thread.

Thread plugs lengths and blank standards are ASME B47.1. They can be found at different product websites. Really anywhere where quality tools are sold using thread gages makes the jobs go on without a hitch. Machine shops as well as welding fabricator shops make jobs easier with this thread gage. When you’re cutting threads for an inside diameter pipe caps or cutting pipe for a plumbing job this tool works great for checking pitch and angle.

Go to any of the retailer’s location to check out one of these babies. There’s nothing like feeling quality in your hands. So what are you waiting for? Get on down to your local hardware store or get on to your favorite website to order some these for your home project or industrial shop today. You can’t go wrong with ACME thread gages.

.

Acme Thread Gages

A c m e thread gages is a screw pitch gauge, used to measure lead or pitch. The larger gauge is an ISO metric, which is in the middle for measuring for and the lower one is for screws.

The gauges are used to determine the pitch of a thread on screw in a tapped hole. It allows the user to determine the profile of the thread, by pitch and shape.

A c m e thread gauges, is durable, resistant to wear and versatile. The thread has a 29o angle, with a thread height half pitch, where the crest and peak are level. The gauges are also used to check the external thread, and the spile's internal thread.

A c m e thread also provide the following general purpose items:

* Centralizing A c m eThread

* General- purpose A c m eThread

* Stub-A c m e Thread

The A c m e thread gauge is strong and allow the use of a split nut, central movements, conveyors, jacks, testing machines, valve, steering mechanism, pressure cylinders, camera movements, and hose connectors. The diameters are always associated with pitches and meet the requirements and tooling, to a minimum effect to reduce cost.

the 284 A c m e thread gauge is a standard cutting and setting the tread mechanism. It is usually used to replace, the thread in a machine cylinder. It is very strong, and the edges is hard. The use of the angle in the thread is used to check the large precision at the end of the gage.

The ring gages has 3 classes of fit and is compliant to ASME B1.5-1997 and the B47.1.

ACME thread gages are worth the investment and use, because they can be customized, the provide high quality thickness, proper cutting for angles, and the appropriate tools get the job done effectively.